Most industrial enterprises in Russia and the CIS require deep modernization. However, the lack of original or up-to-date as-built documentation, schematics, and layout plans significantly complicates the project development stage. Terrestrial 3D laser scanning enables a substantial reduction in costs for obtaining accurate and current information about a facility. IMG Engineering provides fast and high-quality comprehensive engineering services, including terrestrial laser scanning, 3D modeling, and reverse engineering of existing production facilities

.

3D laser scanning technologies have proven highly effective in enhancing the efficiency of construction and installation works (CIW) by improving quality control and accurate measurement of work volumes carried out by contractor construction organizations. Terrestrial laser scanning allows for a quick and accurate determination of the actual dimensions and positions of structural elements and installed equipment, allowing measurement data to be superimposed onto the project’s 3D model for precise identification of deviations from design specifications.

Advantages of Terrestrial Laser Scanning for Industrial Facilities and Benefits for the Client:

- Time savings: 3D laser scanning significantly reduces the time required for all field measurement activities on site.

- Accurate 3D data: Only laser scanning technology provides a 3D model based on actual, real-world measurements — not outdated or incomplete drawings.

- High accuracy: The deviation in the 3D model obtained via laser scanning does not exceed 1–2 cm.

- High level of detail: Only laser scanning can capture the exact position of pipelines at the top of a column, the true geometry of reactor or tank walls, and hull defects — with scanning resolution down to 1–2 cm.

- Versatility: 3D laser scanning data can be directly imported into CAD software from any vendor, including Autodesk, AVEVA, Intergraph, Bentley, and others.

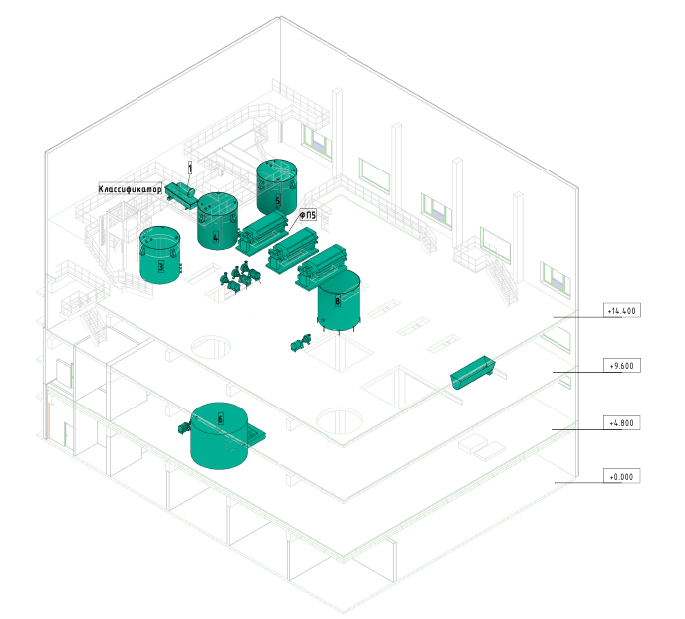

Upon completion of the project, the Client will receive the as-built 3D model of process units, industrial site, or workshop, along with all necessary drawings, cross-sections, elevations, and the facility’s site plan (in 2D or 3D format), or a point cloud.

Types of Work and Engineering Surveys Performed

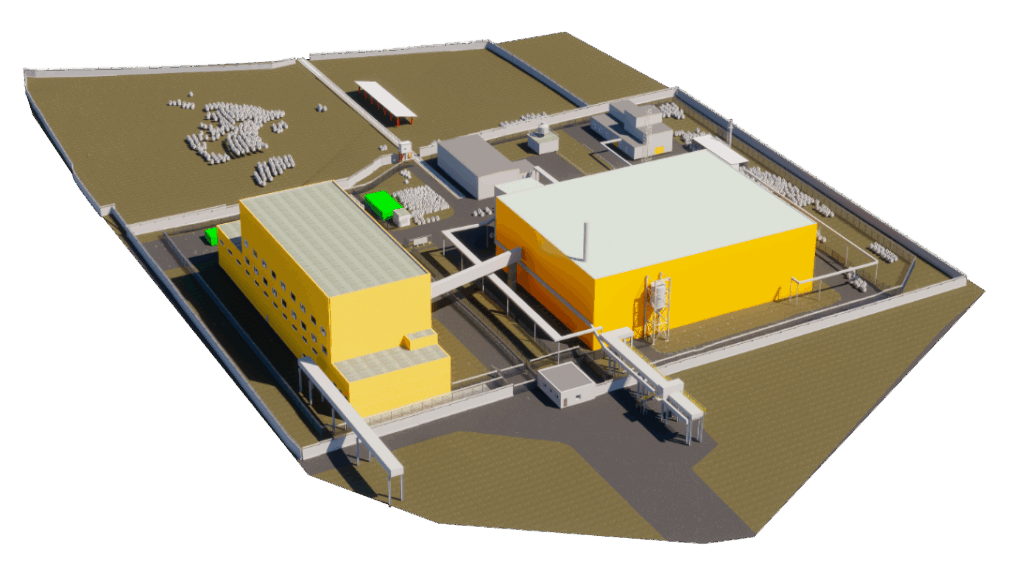

- Creation of 3D models of process units and industrial facilities.

- Development of as-built drawings, cross-sections, and elevations.

- Creation of site plans for industrially developed areas.

Stages of Work Performed

- Fieldwork — 3D laser scanning of the facility

- Post-Processing — Registration and alignment of individual scans into a unified point cloud, georeferencing to the original coordinate system

- Modeling — Development of 3D models or as-built drawings (floor plans, cross-sections, elevations)

Work results

- Panoramic photographs;

- 3D model of the facility in Autodesk-compatible format;

- As-built drawings of the facility;

- Registered point cloud of the facility’s as-built measurements for construction progress monitoring.