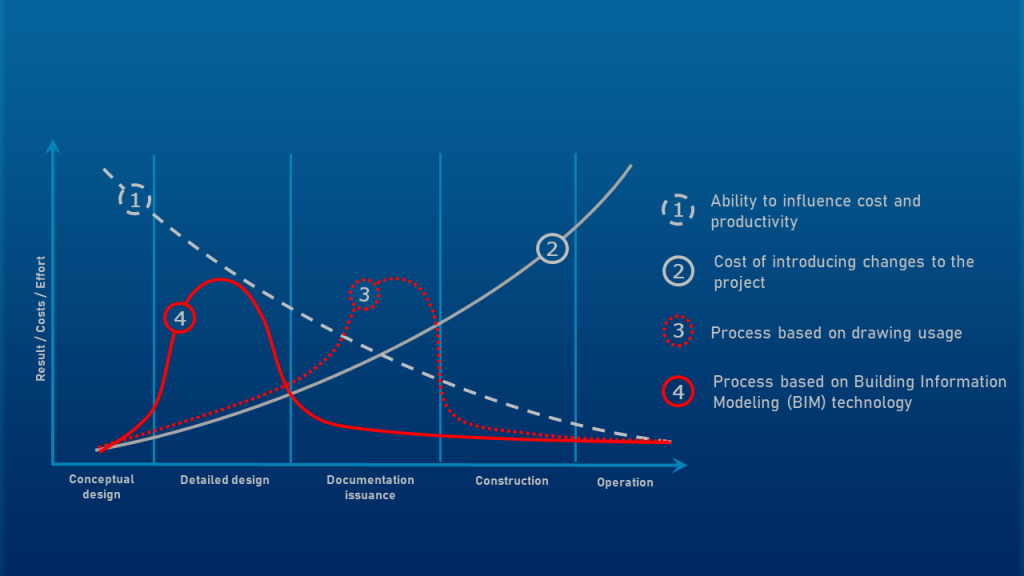

Industrial engineering, design, and construction are increasingly demanding the implementation of more sophisticated systems and tools for managing new construction and modernization projects. Traditional methods based on paper-based documentation are rapidly being replaced by more advanced and innovative solutions. One such solution is BIM (Building Information Modelling), a process that enables a team of specialists—including architects, engineers, designers, technologists, and others from multiple stakeholders—to collaborate on design and planning within a single 3D model. The transition to BIM is driven by the need to collect, track, and process large volumes of information throughout the design, construction, and operation of capital construction projects, as well as to make continuous data adjustments during project implementation. IMG Engineering specialists have mastered and actively utilize all the capabilities and advantages of BIM technology.

Construction of a virtual facility prior to the on-site construction

During the design process, accurate virtual replicas of materials, structures, equipment, construction machinery, and other components are used. The foundation is a virtual built model, based on which projections, drawings, cross-sections, and other design documentation are developed.

Costs optimization on works and materials by up to 40–50%

- Thanks to accurate and up-to-date material specifications. Cost control and verification of submitted estimates are possible at all stages of project implementation.

- Consistently high quality of design solutions ensures uninterrupted work execution and helps avoid additional expenses.

- Rapid response to construction errors and deficiencies, with prompt development of optimal corrective solutions.

Construction without “Unforeseen Issues”

BIM technology helps avoid the most common design errors, such as the inability to implement (build or install) a design solution. This typically occurs because each component, section, or line is considered in isolation from the entire site. As a result, issues arise due to unaccounted-for structural conditions, equipment dimensions, or piping constraints. These problems often lead to work stoppages and unexpected cost overruns. Statistics show that on average, 40% of design solutions developed using traditional drafting methods are revised during construction due to non-compliance or inaccuracies.

BIM technology enables the creation of a complete virtual model of all structures, equipment, and materials within a unified environment. Every design element, component, or material is fully detailed and can be implemented on-site without “surprises.”

Controlled change management process

Unfortunately, various errors inevitably occur during construction. The task of project developers is to quickly find an optimal solution in complex situations. BIM-based design technology allows for timely:

- Analysis of the impact of errors on the construction process and the project as a whole;

- Identification of the optimal solution, considering interdependencies between all components, structures, and equipment;

- Fast and accurate implementation of corrections into the model. Unlike standard methods, which require revising every sheet of design documentation, this approach reduces the time required to make changes by more than 10 times.

Automatic calculation of materials and equipment (specification generation)

In conventional design systems, equipment and material lists (specifications) are created with the involvement of the designer. This can lead to errors and loss of specification accuracy after each project change (each correction requires manual recalculation). BIM technology enables automatic specification generation. When changes are made to the project, the specification is automatically updated. As a result, the client always has access to an up-to-date list of materials and work volumes.

Real-time construction process management

BIM technology allows for contractor oversight, tracking of key performance indicators and deadlines at any required scale—from strategic planning down to individual workers on specific sections of the site.

IMG Engineering LLC is a member of the self-regulatory organization Association of Design Organizations “MRP” (MezhRegionProekt) and holds the right to perform design documentation preparation for especially hazardous, technically complex, and unique capital construction projects (excluding nuclear energy facilities).питального строительства (кроме объектов использования атомной энергии).